Manufacturing of High-Performance Molds for Medical parts…

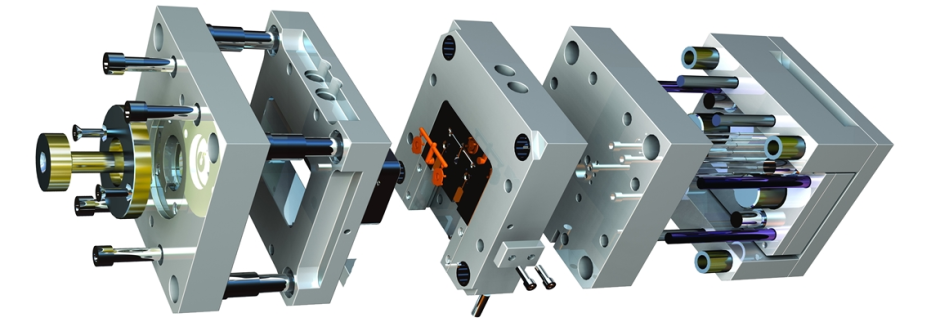

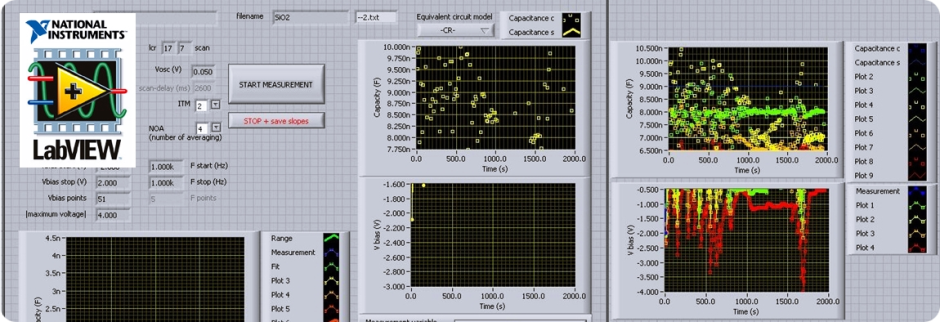

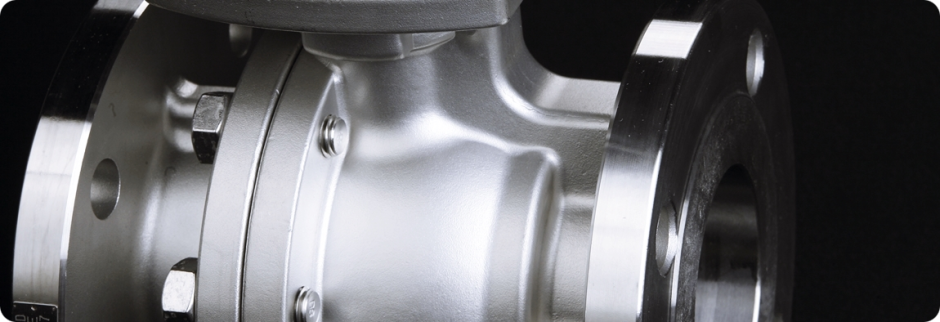

The production of plastic components for Medical and laboratory applications demands maximum precision and perfection. Daedalus Engineering has gained major expertise in the production of molds for Medical and laboratory parts that meet all medical requirements. The clean-room compliance of our molds, as well as their outstanding stability during all production processes and their above-average service life has impressed our customers all over the world.

Daedalus Engineering has earned itself a place among the world’s manufacturing elite by providing customers with value-driven molded products that consistently, and where possible, exceed the expectations of customers & partners who demand the highest standards of services.

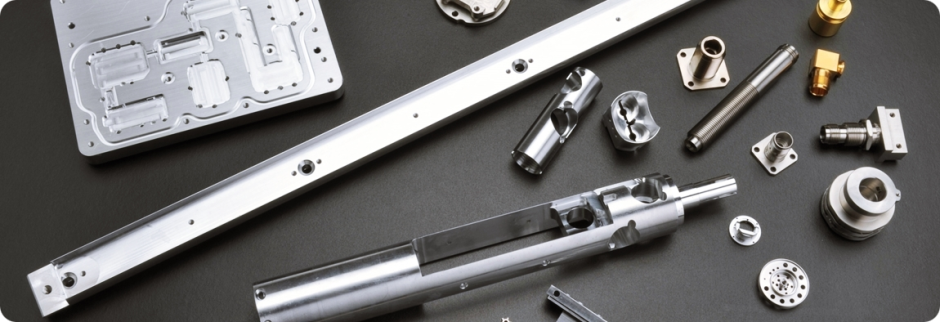

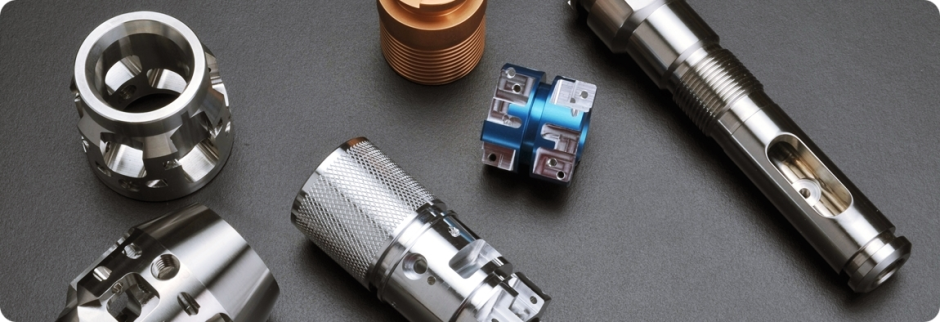

From design and engineering, to mold construction and part production, Daedalus Engineering offers the finest and most reliable worldwide injection molding services. Our success can be measured by our ever-increasing client database and wide diversity of custom molded products.

Each project is managed by molding professionals with the knowledge, experience and a zero-defect mentality to ensure optimized designs, quality, rapid cycle-times, and on time delivery.

For our customers, we solve problems that were unable to resolve elsewhere. We have acquired many molds from other molders that were unable to meet the challenges of difficult product designs, highly engineered resins, precision tolerance parts, or complex tooling.

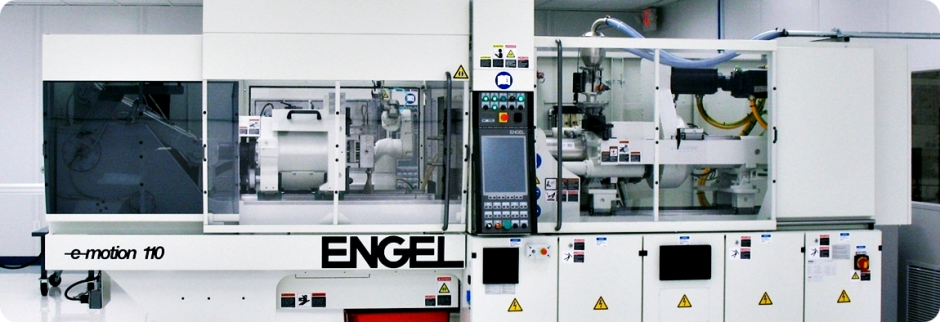

In order to supply a full-range service, Daedalus Engineering, thanks to his extensive knowledge across the industry, acts as a trader to offer a turnkey solution. All our partnerships are with outstanding professional’s that employs state-of-the art technologies to provide its customers with precision molded products. The injection press equipment, ranging in size from 20 to 500 tons, (grey zone and Clean-room) is capable of manufacturing plastic products to the most tough of engineering specifications.

Our broad experience enable us to deliver an extraordinary level of quality molded products, made in over ninety different types of engineered thermoplastic materials, to our customers. Molding parts in Polysulfone, PEEK, TPX, PVC, TPE, PPO, PEI, PPS, PP, PE, Acetal, Nylon, Acrylic, ABS, Polyesters (PBT and PET), Polyurethane, Polycarbonate, Silicone, and many others, are common daily occurrences at Daedalus Engineering.

We believe in partnering with you, our customer, to develop a close working relationship so that we can share our expertise at all stages of the injection molding project. We are interested in becoming a value added partner who will assist you in increasing your profitability.